Carboxymethyl Cellulose (CMC) is a high-efficiency, water-soluble hydrocolloid derived from natural cellulose. It serves as a versatile thickener, binder, stabilizer, and rheology modifier across numerous industries. Our CMC powder is engineered to deliver superior performance and process efficiency, making it an indispensable ingredient for formulation engineers in the food, beverage, pharmaceutical, and personal care sectors who seek reliable texture and stability control.

Our CMC is manufactured to precise specifications to guarantee reliable and consistent performance. The table below lists the typical properties for our standard food grade (Model: FH9). Please contact us for specifications on other grades.

| Parameter | Specification | Test Method |

|---|---|---|

| Appearance | White to off-white, free-flowing powder | Visual |

| Purity (on dry basis) | ≥ 99.5% | Titration |

| Viscosity | 1500 – 2500 mPa.s (cps) | 1% Solution, 25°C, Brookfield LV, #3 Rotor, 30 rpm |

| Degree of Substitution (DS) | 0.7 – 0.9 | Conforms to FCC/E466 |

| pH Value | 6.5 – 8.0 | 1% Solution |

| Moisture Content | ≤ 8.0% | Gravimetric (Loss on Drying) |

| Particle Size | 95% passes 80 mesh (180 µm) | Sieve Analysis |

| Lead (Pb) | ≤ 2 mg/kg | AAS/ICP-MS |

| Total Plate Count | ≤ 1000 cfu/g | USP/BAM |

| Yeast & Mold | ≤ 100 cfu/g | USP/BAM |

| E. coli & Salmonella | Negative in 25g | USP/BAM |

Rigorous Testing & Batch-to-Batch Consistency Quality is the core of our manufacturing philosophy. Every production batch of Carboxymethyl Cellulose undergoes a full suite of tests to ensure it strictly conforms to the established specifications. We document key performance indicators, especially viscosity and purity, to provide our clients with the batch-to-batch consistency required for large-scale automated production. This diligence minimizes production fluctuations and ensures your final product quality is maintained.

Available Documentation for Your Compliance Needs We provide a comprehensive documentation package to support your quality assurance, regulatory affairs, and import/export requirements.

Food & Beverage

Pharmaceuticals

Personal Care

Formulation Tip: How to Disperse CMC Powder To ensure complete, lump-free hydration, we recommend two primary methods: 1) Before adding to the liquid phase, thoroughly pre-mix the CMC powder with other dry ingredients in your formula (e.g., sugar, starch, flour) at a ratio of at least 1:5 (CMC to other solids). 2) If adding directly to water, slowly add the powder into the vortex created by a vigorously agitated liquid. This high shear helps separate the particles and allows them to hydrate individually.

pH, Heat, & Salt Tolerance Our CMC exhibits excellent viscosity and functional stability across a wide pH range (typically 4.0 to 10.0). While viscosity may decrease in highly acidic or alkaline systems, its functionality remains effective. The product is stable under standard heat processing conditions, including pasteurization and UHT (short-time ultra-high temperature), and shows good tolerance to moderate salt concentrations.

Recommended Storage Conditions For optimal performance and shelf life, store in a cool, dry place (below 25°C, <60% RH) in its original, unopened packaging. Keep away from direct sunlight, moisture, and strong odors. The recommended shelf life is 24 months from the date of manufacture.

Carboxymethyl Cellulose, also known as Cellulose Gum or E466, is recognized and approved as a safe multi-purpose food additive by major global regulatory bodies, including the U.S. FDA (21 CFR 182.1745), the European Food Safety Authority (EFSA), and the Joint FAO/WHO Expert Committee on Food Additives (JECFA). It is a water-soluble dietary fiber that is not absorbed by the human body. This product is for B2B manufacturing use only and not for direct consumption.

1. What are the main grades of your CMC?

We offer multiple grades, primarily distinguished by viscosity and degree of substitution. Our most common grades range from low viscosity (approx. 50 cps) for slight mouthfeel improvement to high viscosity (>4000 cps) for significant thickening. Please contact our technical team to discuss your specific application.

2. What is the best way to disperse CMC to avoid clumping?

The most effective method is to pre-mix the CMC powder with other dry ingredients at a ratio of at least 1:5 before adding it to water. Alternatively, add it slowly into the vortex of a highly agitated liquid.

3. Is this CMC product suitable for vegan and gluten-free formulations?

Yes. Our Carboxymethyl Cellulose is derived from plant-based cellulose and contains no animal products or gluten, making it perfectly suitable for vegan, vegetarian, and gluten-free product development.

4. What documents are provided with each shipment?

Every shipment is accompanied by a lot-specific Certificate of Analysis (COA) and the corresponding Material Safety Data Sheet (MSDS). Other documents, such as a Certificate of Origin or compliance statements, are available upon request.

5. What is your minimum order quantity (MOQ) and typical lead time?

Our standard MOQ is 25 kg (one bag). Lead times vary by location and order volume, but we typically ship from our warehouse within 2-3 business days of order confirmation. Please request a formal quote for precise details.

Xi’an Best Bio-Tech Co., Ltd. is a professional manufacturer and exporter of high-quality natural herbal extracts.

We specialize in research, production, and global trade of botanical ingredients, serving customers in 60+ countries.

Located in Yangling, China, our GMP-certified factory is equipped with advanced extraction lines and full-spectrum lab testing, including HPLC, UV-VIS, and microbiological analysis.

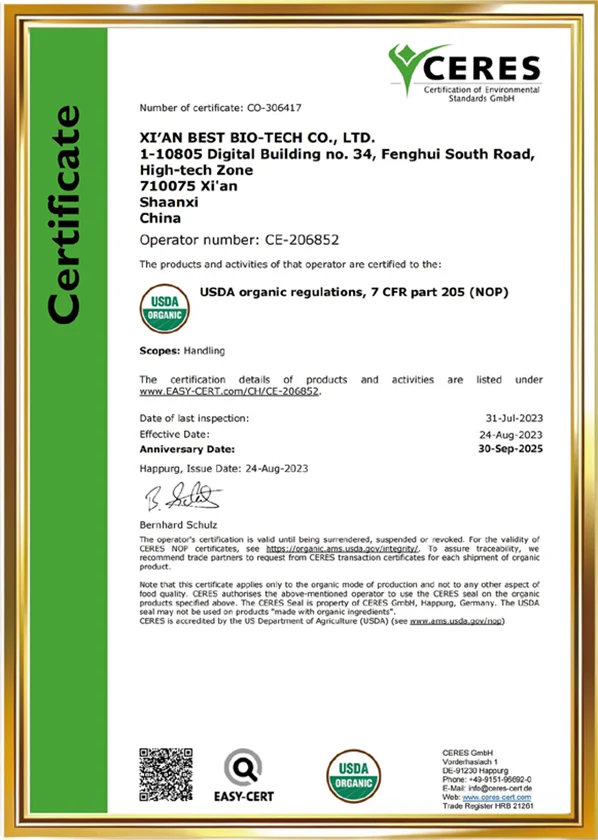

We’ve passed a full set of international certifications to ensure our products meet the highest standards in every market

1000+ Products Available for Custom Manufacturing

lron-ringed Cardboard Drum

Aluminum Foil Bag

25kqs by Drum/Carton

Bottles\Foil Bags

| MOQ | 1kg (bulk) / 500 units (OEM) |

| Lead Time | 5–10 working days |

| Packaging | 1kg foil bag / 25kg drum / Custom |

| OEM Formats | Sachets, Capsules, Labeling, Formulation |

| Shipping | CIF, FOB, DDP, Air/Sea freight |

| Payment | T/T, PayPal, L/C (bulk only) |

BSTBIO will select the best shipping options based on the final order amount. We will ship your products using the following methods:

Fast shipping, technical support, and OEM available – Inquire now!